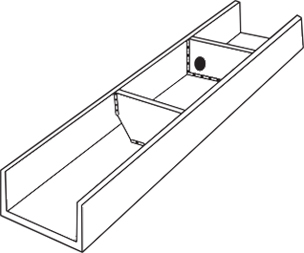

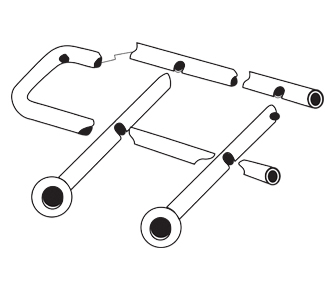

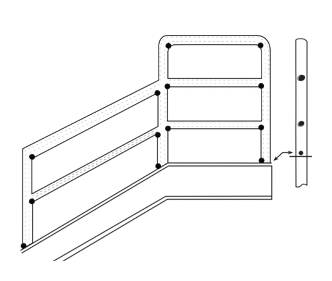

Design For Galvanizing

New technologies and creative chemistries continue to evolve the specification and use of hot-dip galvanized metal and steel as new markets emerge.

When planning for the galvanization process, it’s always important to ensure your material is properly audited for any issues that could lead to lower life and quality of your galvanized product. V&S technicians take the time to thoroughly inspect your steel and advise on any defects that need corrected prior to galvanizing. Constant communication with your team throughout the entire process produces superior quality coatings faster and for less.

Below are some common questions we receive from our customers. Please contact us directly for a custom V&S Galvanizing design consultation on your specific need.